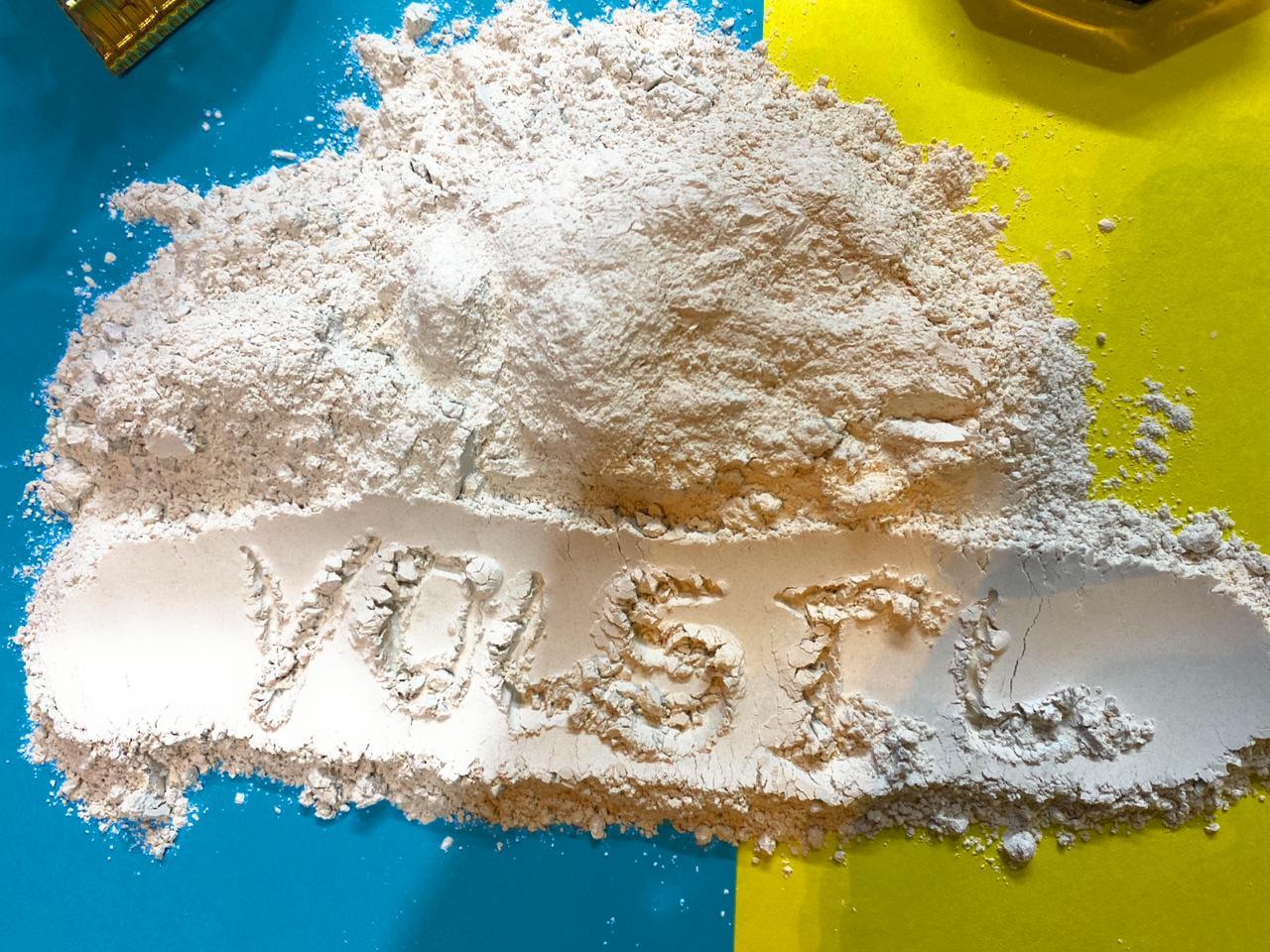

Silica Cement Admixture

9 INR/Kilograms

Product Details:

- Physical Form Powder

- Type Silica Cement Admixture

- Purity HIGH

- Feature High Strength

- Smell No Smell

- Color White

- Usage Construction

- Click to View more

X

Silica Cement Admixture Price And Quantity

- 9 INR/Kilograms

- 1000 Kilograms

Silica Cement Admixture Product Specifications

- Construction

- Silica Cement Admixture

- Powder

- High Strength

- HIGH

- White

- No Smell

Silica Cement Admixture Trade Information

- Mundra Port

- 350 Kilograms Per Month

- 1 Week

- Yes

- Free samples are available

- 20 kg 1 mt

- Asia

- All India

- ISO IGBC

Product Description

Volsil A-Sio2 is a pozzolanic material containing A-Sio2 amorphous silica and minor amounts of residual minerals Test results indicated that the concrete specimens containing 5%, 10 %, 15 %, 20% A-Sio2 replacement by weight for cement had the best compressive and flexural strength and the replacement of cement separately and together using a super plasticizing admixture could be utilized to improve the mechanical properties of the conventional concrete mixtures Amorphous silica (a-SiO2) in fine-grained form possesses a high pozzolanic activity which makes it a valuable component of blended binders in concrete production. The origin of A-SiO2 applied in cement-based composites is very diverse. SiO2 in amorphous form is present in various amounts in quite a few supplementary cementing materials (SCMs) being used as partial replacement of Portland cement. In this work, the applicability of a commercially produced silica powder as a partial replacement of Portland cement in cement paste mix design is investigated. Portland cement CEM I 42.5R produced according to the EU standard is used as a reference binder. silica is applied in dosages of 5 and 10, 15, 20 % by mass of cement. The water/binder ratio is kept constant in all the studied pastes. For the applied silica, specific surface area, density, loss on ignition, pozzolanic activity, chemical composition, and SiO2 amorphous phase content. For the developed pastes on the basis of cement-silica blended binder, basic physical properties as bulk density, matrix density, and total open porosity are accessed. Pore size distribution is determined using MIP analysis. Initial and final setting times of fresh mixtures are measured by the automatic Vicat apparatus. Effect of silica cement admixture on mechanical resistivity using compressive strength, bending strength, and dynamic Young's modulus measurement. The obtained data gives evidence of the workability of paste mixtures with silica, whereas the setting process is accelerated. On the other hand, the reaction activity of silica with Portland cement minerals results in a slight decrease of porosity and improvement of mechanical resistivity of cement pastes containing a-SiO2.Nowadays, supplementary cementitious materials (SCMs) are widely used for preparing cement composites either in blended types of cement or added separately to the composite mix. The usage of active silica-rich materials represents an appropriate solution to partially replace Portland cement In addition, most of the SCMs are industrial by-products and their utilization in cement-based composites brings environmental and economic benefits. The admixture of different SCMs usually modifies the properties of cement composite to a certain degree both in the fresh and hardened states. These changes are influenced by different chemical and mineralogical composition, as well as different particle size characteristics which are connected with water requirement and also reactivity [2]. Active silica particles help to fill voids between particles of cement and other components because they are significantly smaller. This filler effect supports the formation of a denser microstructure because the gaps between the particles are minimized and bridged by hydration products

FAQs of Silica Cement Admixture:

Q: What is the chemical composition of Silica Cement Admixture?

A: The chemical composition of Silica Cement Admixture is SI.

Q: What is the purity of Silica Cement Admixture?

A: The purity of Silica Cement Admixture is high.

Q: What is the physical form of Silica Cement Admixture?

A: Silica Cement Admixture is in powder form and is white in color.

Q: What is the application of Silica Cement Admixture?

A: Silica Cement Admixture is used in concrete construction for high strength.

Q: What is the strength of Silica Cement Admixture?

A: Silica Cement Admixture provides high strength for construction purposes.

Enter Buying Requirement Details